Related Products

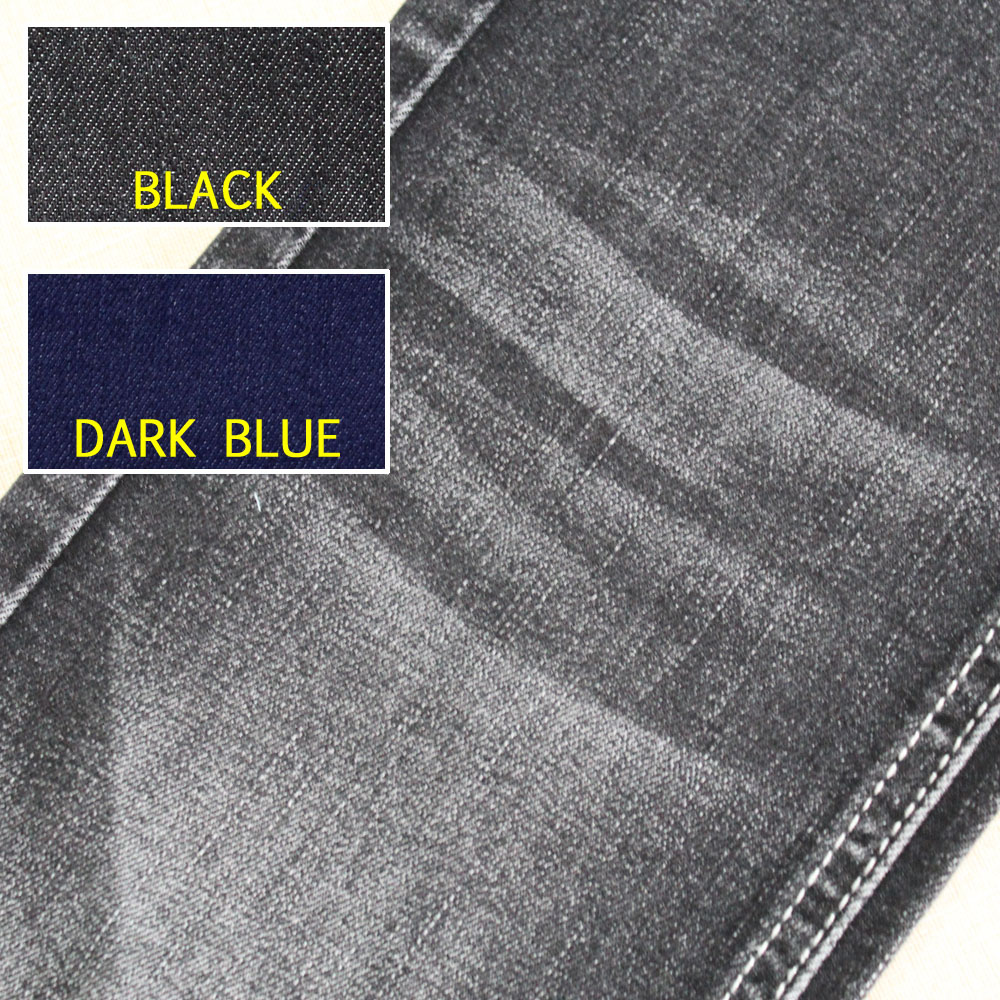

| Material | Cotton/Polyester/Rayon/Spandex |

|---|---|

| Trade Terms | EXW, FOB, CIF, CNF, DDU, DDP, etc |

| Supply Ability | 70000meters / Day |

| Port | Guangzhou |

| Payment | L/C, D/A, D/P, T/T, Western Union, MoneyGram, PAYPAL payments for offline orders. |

| Packaging Detail | Roll packing with plastic paper |

| Shipping | BY SEA, BY AIR OR BY EXPRESS |

Copyright © 2021 Foshan Nanhai Hongxinghong Weaving Co., Ltd. | All Rights Reserved